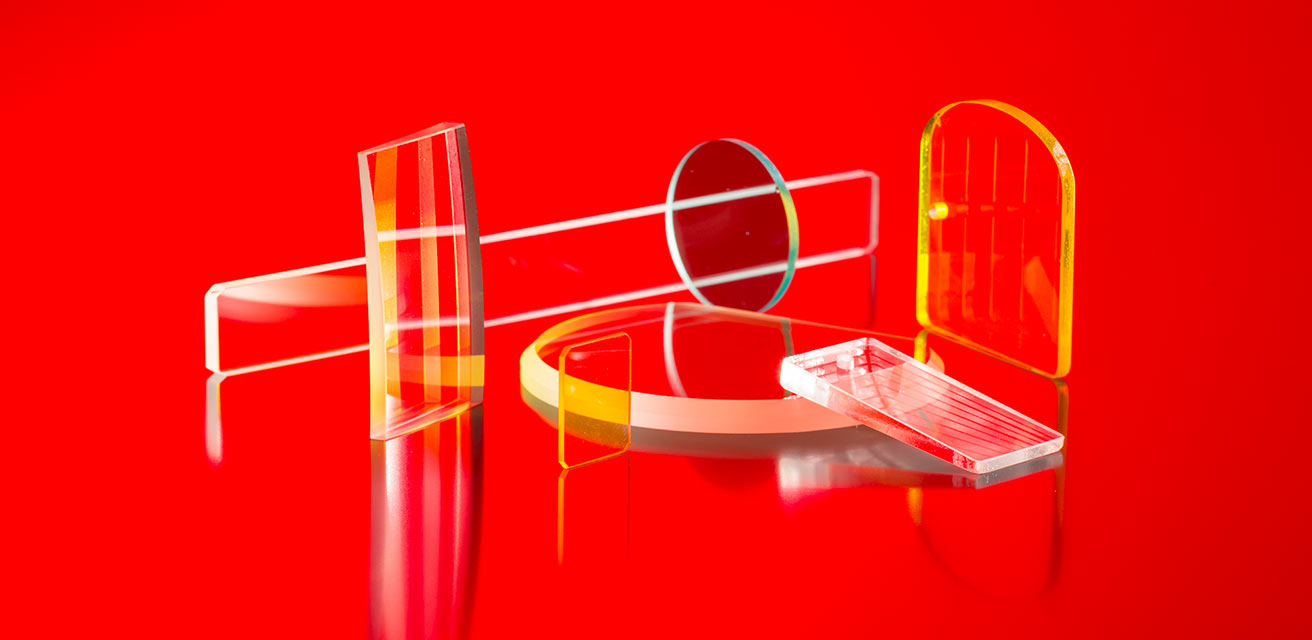

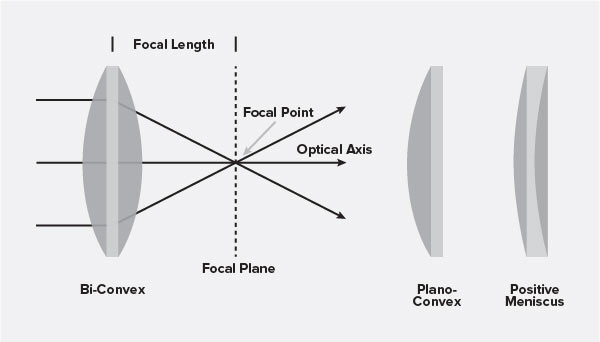

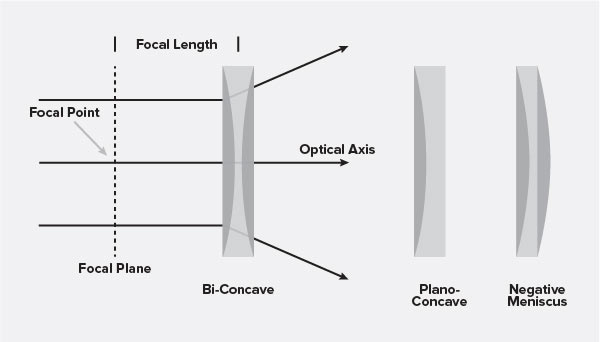

Spherical lenses have at least one surface with a constant radius of curvature. There are two categories of spherical lenses: Convex (Converging) lens and Concave (Diverging) lens.

The manufacturing process of spherical lenses begins with a quote created by a Manufacturing Engineer. The Manufacturing Engineer then designs and orders a near-net-shape optical glass blank. The optical glass blanks are then delivered to the production line once we receive the material. Once we process the order, the first step is to have diamond ring tools to generate the radius into the glass blank. A series of progressively smaller grit diamond wheels or loose abrasive material is then used to grind the lens blank finely. Finally, the polishing process uses pitch or polyurethane pads and a cerium oxide slurry to finish the spherical lens surface. The finished spherical lenses are then either shipped to the customer or retained in the facilities for further treatment with processes such as custom coatings and truncations.

At LaCroix Precision Optics, our vast inventory of conventional and CNC production equipment allows the freedom to manufacture your lens designs most efficiently and cost-effectively.

- Precision centering

- Custom truncations

- Off-axis spherical lenses

Coatings

We have extensive in-house coating capabilities to meet your requirements. See our coating capabilities.

| Uses for Optical Lenses | ||

|---|---|---|

| Surgical loupes | Microscopy | Multi-spectral imaging |

| Telescopes | LASIK devices | Machine vision |

| Ophthalmology | Threat detection | Laser target designators |