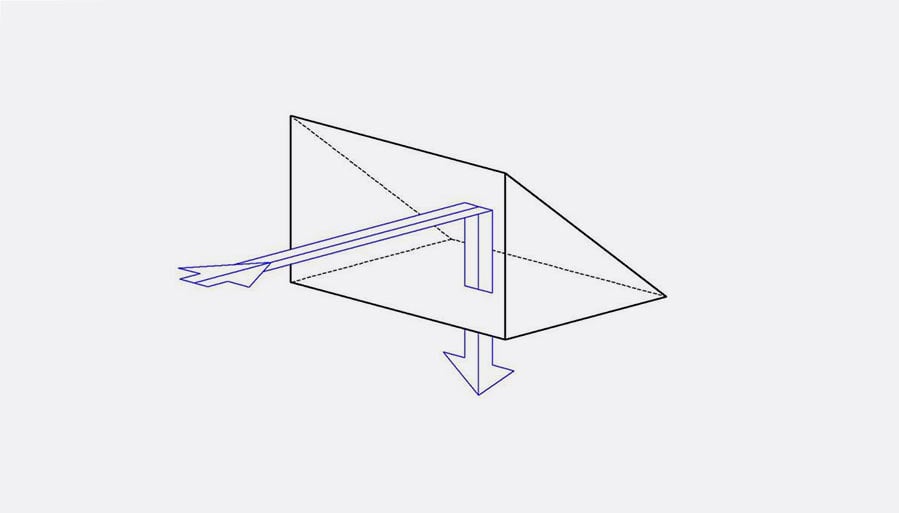

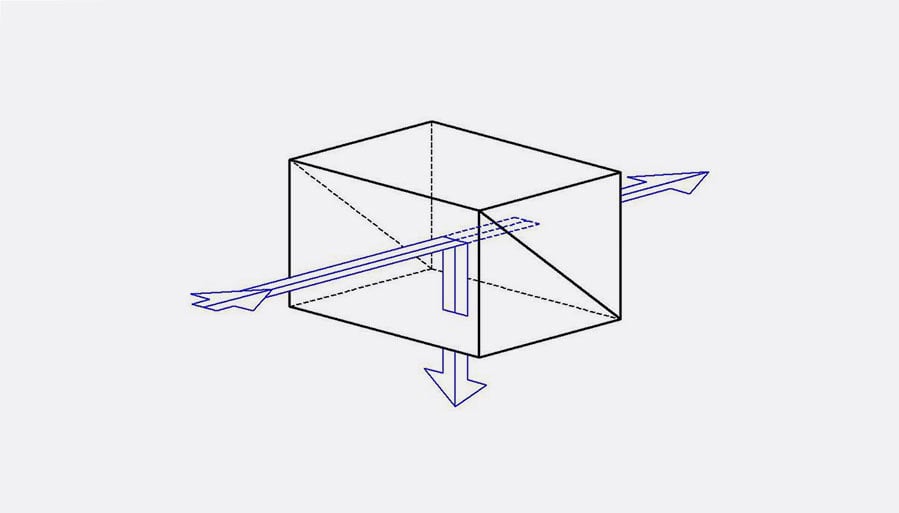

Prisms & Beam Splitters

Precise Angles Control the Path of Light

Controlling light for image and beam manipulation requires meticulous attention to angular precision, surface quality, and material selection.

LaCroix's prisms & beam splitters follow strict surface and dimensional tolerances. Standard angular accuracies begin at 3' and can reach less than or equal to 1'.

Capabilities in Prisms & Beam Splitters

-

6mm - 100mm

-

90 degree, anamorphic, cube, & wedge prisms

-

Prototypes to volume production

-

Surface accuracy up to λ/10

-

High-precision optical machining

-

Broad range of materials including optical glass (Schott, Ohara, Hoya, CDGM), fused silica, fused quartz, filter glass, and float glass.

Applications for Prisms & Beam Splitters

-

Binoculars

-

Telescopes

-

Ophthalmology

-

Microscopy

-

LASIK devices

-

Threat detection

-

Multi-spectral imaging

-

Machine vision

-

Laser target designators

Manufacturing Optical Prisms, Beam Splitters

Fabrication begins with a LaCroix Manufacturing Engineer dedicated to seeing your project from sketch to completion.

We follow a step-by-step process with rigorous quality checks along the way

1. Optical Design

Our engineering team will collaborate with you and provide suggestions for making your optics manufacturable.

2. Shaping, Grinding

As the shape takes form through generation, fine grinding forms the prism to your specifications.

3. Polishing, Cementing, Finishing

Prism surfaces are polished and cemented together, and are ready for coating and metrology as needed.

Optical Coatings from UV-SWIR

Use our extensive in-house coating capabilities to meet your requirements.

Prism & Beam Splitter Resources

We've developed a variety of resources to help you determine the best optics for your application. Explore our full library of resources.