Achromatic Lenses

Minimize Chromatic Aberrations for Sharp, Clear Images

LaCroix manufactures and assembles thousands of achromatic lenses every week, including triplets and aspheric achromats.

Expertise in Achromats

-

4mm - 150mm

-

Surface accuracies up to λ/20

-

Centration to seconds

-

Broad range of materials including optical glass (Schott, Ohara, Hoya, CDGM), fused silica, fused quartz, filter glass, and float glass.

-

Optical engineering through manufacturing

-

Custom truncations

-

Off-axis spherical lenses

Achromat Applications

-

Surgical loupes

-

Telescopes

-

Ophthalmology

-

Microscopy

-

LASIK devices

-

Threat detection

-

Multi-spectral imaging

-

Machine vision

-

Laser target designators

Achromat Lens Manufacturing

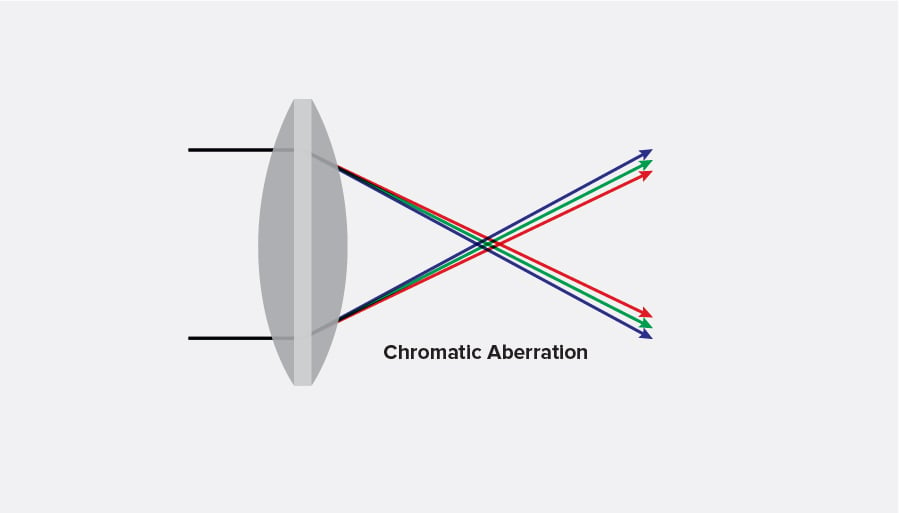

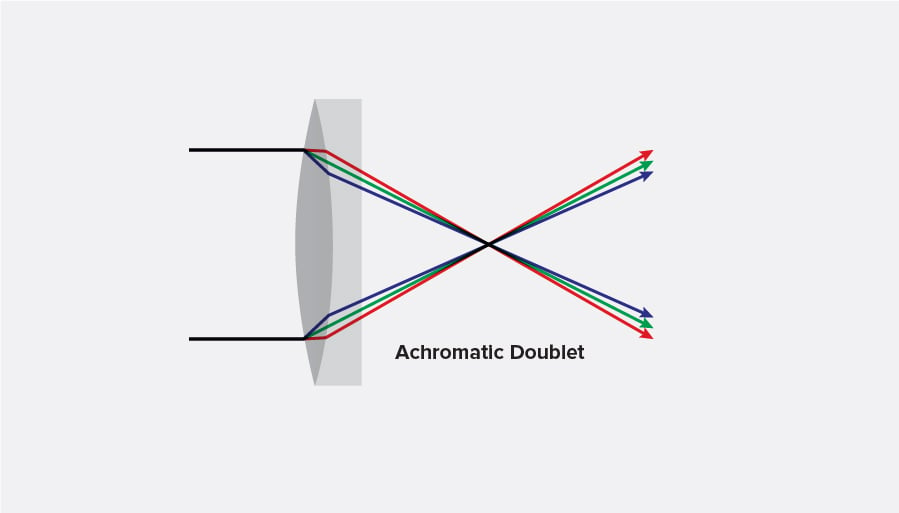

What is an achromat?

An achromat combines a convex lens and a concave lens, often made with different materials with different refractive properties, to focus light to the same spot, correcting for chromatic aberration and resulting in a sharper image.

You'll be assigned a LaCroix Manufacturing Engineer dedicated to seeing your project from sketch to completion.

We follow a step-by-step process with rigorous quality checks along the way.

1. Optical Design

Collaborate with our engineers to verify your print. We'll work with you to recommend the right optical material for production.

2. Crown and Flint Manufacture

We'll use a lower dispersion material for the convex crown, and a higher dispersion material for the concave flint.

3. Optical Alignment and Assembly

After precision alignment in both the optical and mechanical axis, lenses are cemented together using a specialized index-specific optical cement. The optical cement is then cured using UV light.

4. Centration

After assembly, some of the doublets are centered to the final diameter while others are pre-centered before cementing. Doublets can also be blackened after assembly to reduce scattering, which can be beneficial in some optical applications.

5. Test and Measurement

Interferometry, surface roughness, radius of curvature, aberrations, and more.

In-House Custom Optical Coatings

We have extensive in-house coating capabilities to meet your requirements.

Achromatic Lens Resources

Looking to learn more about achromatic lenses? Use our resources.