Optical Windows & Wedges

Precision Optics That Protect, Transmit, Deflect, & Disperse

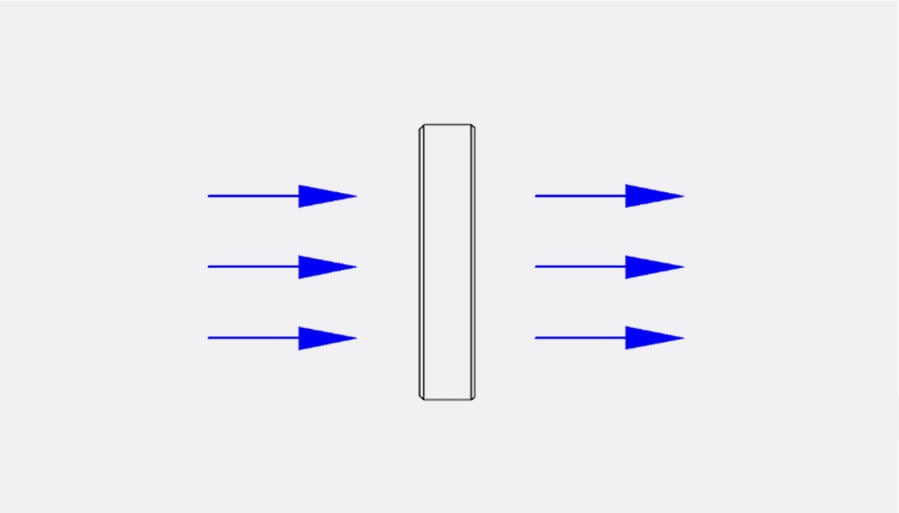

Optical windows protect sensitive detectors and internal optical components from harsh environmental conditions while maximizing light transmission without distortion.

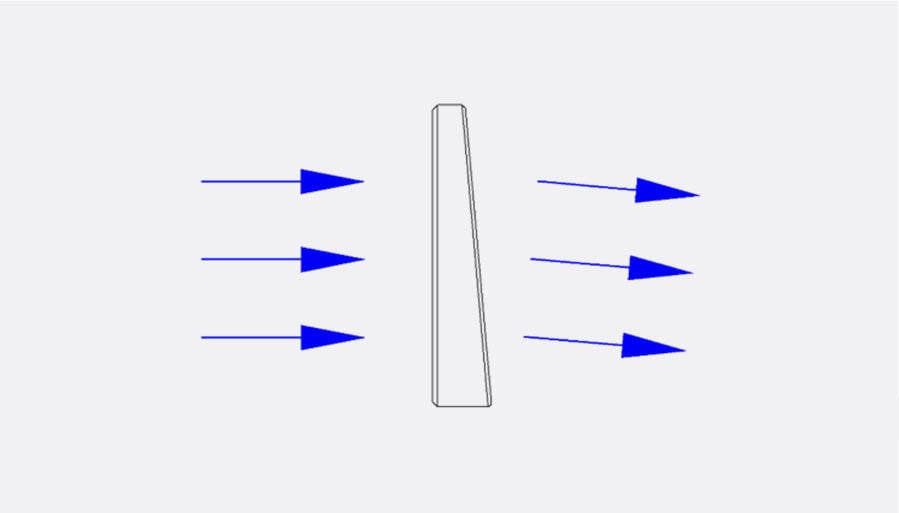

Optical wedges with rigorously controlled angles manipulate light propagation for intricate beam steering, finely tuned spectral manipulation, and tight dispersion compensation.

LaCroix demands the highest quality in precision-crafted flats, windows, and wedges so your system meets or exceeds performance specs.

Precision Optics: Design Manufacturing, & Metrology

-

Custom optics

-

Optical assembly

-

Design for Manufacturability

-

Interferometry, profilometry

Optical Window and Wedge Applications

-

Debris shields

-

Telescopes

-

Ophthalmology

-

Microscopy

-

LASIK devices

-

Threat detection

-

Multi-spectral imaging

-

Machine vision

-

Laser target designators

Manufacturing Precision Optical Windows and Wedges

LaCroix's step-by-step optical design, volume manufacturing, and rigorous quality control processes bring new levels of precision to your optical system.

1. Optical Design

Partner with our Manufacturing Engineers to verify your design or make suggestions on optimizing it for manufacturability and performance.

2. Grinding, Polishing

Planar parts are processed in one of two ways: single-sided with multiple parts blocked on flat tools, or double-sided using specialized machines that process both sides at once. In both cases an oversized blank will be generated, fine ground, then polished.

3. Processing

Coming off the pitch lap, the finished surface will be protected and the second surface will be processed. Parts off the double-sided polisher will continue through the plant for further processing. In-house precision tooling induces angles in optical wedges.

LaCroix's Production Technicians to optimize the manufacturing process with a combination of CNC and conventional manufacturing methods. Special proprietary alignment devices are used to ensure the optical axis of the different elements can be maintained within seconds.

AR Coatings, Custom Optical Coatings

Our extensive in-house coating capabilities meet your strictest requirements.

Optical Windows and Wedges Resources

We've developed a variety of resources to help you determine the best optics for your application. Use the resources to the right or explore our full Resource Library.