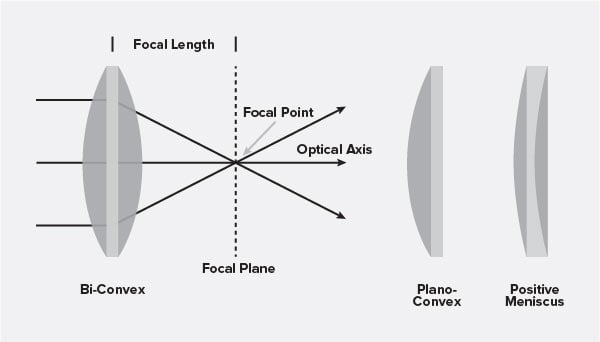

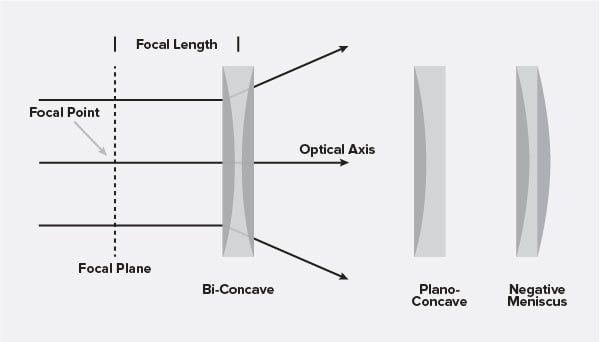

Spherical Lenses

Versatile, Precise Spherical Optics

Spherical lenses are anything but simple. Convex and concave lenses must be crafted for predictable, reliable performance with uncompromising quality.

When you choose LaCroix, your project benefits from our design-for-manufacturability principles. DFM gives your project team the freedom to design and manufacture converging and diverging lenses in the most efficient and cost-effective way, from prototype to high-volume production.

Spherical Optics Expertise

-

Materials selection

-

Optical assembly

-

Design for Manufacturability

Spherical Lens Applications

-

Surgical loupes

-

Telescopes

-

Ophthalmology

-

Microscopy

-

LASIK devices

-

Threat detection

-

Multi-spectral imaging

-

Machine vision

-

Laser target designators

Spherical Lens Manufacturing

Spherical lens fabrication begins with a LaCroix Manufacturing Engineer dedicated to seeing your project from sketch to completion.

We follow a step-by-step process with rigorous quality checks along the way.

1. Optical Design

Our engineering team will collaborate with you and aid with suggestion in making your optics manufacturable.

2. Shaping, Grinding

Diamond ring tools generate the radius into the glass blank. A series of progressively smaller grit diamond wheels or loose abrasive material finely grinds the lens blank.

3. Polishing

Pitch or polyurethane pads and a cerium oxide slurry finish the spherical lens surface.

4. Test and Measurement

Interferometry, surface roughness, radius of curvature, aberrations, and more.

In-House Custom Optical Coatings

We have extensive in-house coating capabilities to meet your requirements.

Spherical Lense Resources

Looking to learn more about spherical lenses? Use our resources.